Tungsten carbide rotary burrs are used across the globe for shaping and cutting. They are also used to remove to sharp edges. For different drilling tasks, the workers make use of these rotary burrs. It is important to get top quality burrs to perform the task properly. Many offline and online companies are offering high-quality burrs at nominal rates.

The tungsten carbide rotary burr set could be used on diverse materials. These materials include cast iron, titanium, steel, cobalt, aluminum, gold, silver, platinum, nickel, fiberglass, copper, plastic, bronze, wood, zinc, and so forth. Diverse cuts of the carbide burrs are ideal for some particular materials. When these burrs are used on the soft metals, then they do not break them at all.

The tungsten carbide rotary burrs companies have to test these burrs properly before selling them. Each burr has to go through diverse tests. If it passes all the tests efficiently, then it is sent to the distribution section. In case, you want to know the way to test these burrs then no issue! We are going to explain it in detail.

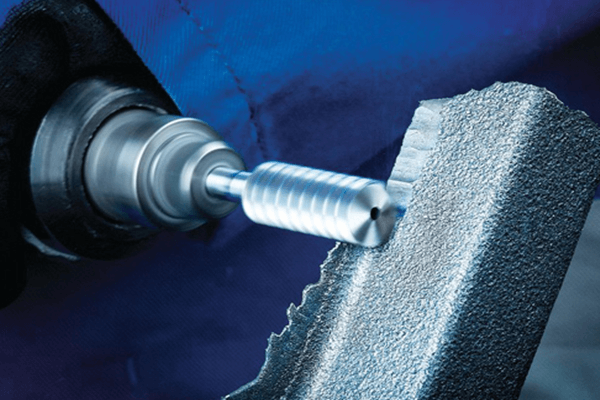

The workers of the company take carbide rotary burr and put them to the grinding test. The workers first grind the hard materials with these burrs. When these burrs perform grinding outstandingly on the hard materials then the workers start grinding the soft materials. If these burrs break or chip the soft materials then they are not good to use. In case, they efficiently grind the soft materials then these burrs are taken for another test.

The workers use tungsten carbide rotary burr set to cut both hard and soft materials. They mark a line on diverse materials one by one and then cut them through the line. If the set of the burrs cut each material competently, then they are considered for cutting.

In the sharp edge test, these burrs are used to remove the sharp edges of different materials. These materials include wood, steel, cobalt, aluminum, and so forth. These burrs should remove the sharp edges and make the surface of the material smooth. If they clear this test competently, then these burrs are excellent in every way. The workers will send them to the distribution section.

The tungsten carbide rotary burrs are used extensively for tool making, tool shaping, metalwork, model engineering, jewelry making, wood carving, welding, grinding, sculpting and cylinder head porting. They are also utilized in the automatic, aerospace, dental and metal industries. These burrs have a long life so you can use them for long production runs.

The most commonly used burr is single cut carbide burr. This burr has an up-cut spiral flute. It is used on hard and stainless steel, cast iron, copper and ferrous metals. It provides a smooth finish to each material. However, the double-cut carbide burrs are also present. They are used on soft steels and non-ferrous materials. Industries use these double carbide burrs for cleaning, finishing, and stock removing.