Application

Carbide burrs are tools used for deburring most hard materials like ceramics, stone, steel, aluminum, plastics and hardwood. They provide precision, and can also be used in cutting, shaping, grinding and chamfering hard materials.

Carbide burrs are tools used for deburring most hard materials like ceramics, stone, steel, aluminum, plastics and hardwood. They provide precision, and can also be used in cutting, shaping, grinding and chamfering hard materials.

Tungsten Carbide burrs can be used on a variety of materials such as metals (including Steel aluminum and cast iron) and all types of wood. It can be used on acrylics, fiberglass and plastics too. Carbide burrs can last for a long time without chipping or breaking so that it’s so good to use them on soft metals like gold,platinum and silver.

Longer life

Run for longer time in production

High stock removal

Suitable to be used on many hard and tough materials

Suitable to be used for deburring, finishing, carving, shaping and smoothing welds, moulds, dies and forgings

Compared with HSS, Carbide Burrs are much harder.

We choose a specially grade of carbide to form our carbide burrs. The Tungsten Carbide is extremely hard so that they can be used in wider range of work than HSS (High Speed Steel).

HSS can’t perform as well as carbide burrs when they are at high temperature. Carbide Burrs can bear hotness and can run for longer time.

Carbide won’t soften at high temperature but HSS burrs is opposite. There is no doubt that carbide is a better choice.

Tungsten Carbide burrs can be used on a variety of materials such as metals (including Steel aluminum and cast iron) and all types of wood. It can be used on acrylics, fiberglass and plastics too. Carbide burrs can last for a long time without chipping or breaking so that it’s so good to use them on soft metals like gold, platinum and silver.

Different cuts of carbide burrs are suited to certain materials. How to choose right carbide burrs for your machines?

Check the points below and you will get the answer.

6

Double Cut: Very efficient stock removal. Creates a small chip. Good finish. Excellent operator control.

3

Single Cut: General purpose fluting. Produces long chips.

1

Nonferrous: For nonferrous materials. Aggressive stock removal.

3SP

Chip Breaker: Provides breakdown in chips. Better control.

4

Diamond Cut: For heat treated and tough alloy steels where control is important. Creates a powder-like chip. Excellent finish.

2

Coarse Cut: Provides large flute area for softer ferrous materials. Fast stock removal.

5

Fine Cut: For general use on hard materials requiring a fine finish.

1.Ensure your burr shank well inserted into your collet and clamped down tightly

2.Never put too much pressure on burrs and keep the burrs moving, focusing on the highest material first

3.Ensure your work is secured tightly to your work bench

4.Never snag or jam your burr into your work

5.Wear eye protection at least, use a full shield for your face will be better

Never try to keep the carbide burr still for too long. It will prevent the burrs from digging and jabbing into your material and avoid causing unsightly marks and roughness.

2. Never Apply Too Much PressureAs with all drill bits and burrs, apply only a little pressure to the burr when it’s working.

If the burrs get too much pressure, the cutting edges of the flutes will chip away or become smooth too quickly, which leads to the reduce of burrs’ life.

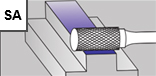

3. Use Diamond Burrs for Carving into StoneSaimeng Tungsten carbide burs keep on excellent quality,SA type for industry use

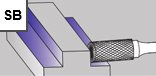

Read MoreSaimeng Tungsten carbide burs keep on excellent quality,SB type for industry use

Read MoreSaimeng Tungsten carbide burrs keep on excellent quality, SC type for industry use

Read MoreSaimeng Tungsten carbide burs keep on excellent quality,SD type for industry use

Read MoreSaimeng Tungsten carbide burs keep on excellent quality,SE type for industry use

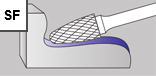

Read MoreSaimeng Tungsten carbide burrs keep on excellent quality, SF type for industry use

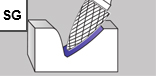

Read MoreSaimeng Tungsten carbide burs keep on excellent quality,SG type for industry use

Read MoreSaimeng Tungsten carbide burrs keep on excellent quality, SH type for industry use

Read MoreSaimeng Tungsten carbide burs keep on excellent quality,SJ type for industry use

Read MoreSaimeng Tungsten carbide burs keep on excellent quality,SK type for industry use

Read MoreSaimeng Tungsten carbide burs keep on excellent quality, SL type for industry use

Read MoreSaimeng Tungsten carbide burrs keep on excellent quality, SM type for industry use

Read MoreSaimeng Tungsten carbide burs keep on excellent quality,SN type for industry use

Read MoreSAIMENG TOOLS has decades of experience in developing and manufacturing dental tungsten carbide cutters. At the same time, it also masters the latest manufacturing technology. The combination of experience and technology ensures that SAIMENG instruments can help technicians to own high performing tools with exceptionally long lifetimes.

SAIMENG TOOLS is popular in dental use. SAIMENG dental carbide burrs feature an extra coarse, coarse, double cut, fine, medium fine and super fine pattern, developed for finishing stone & plaster, chrome and cobalt alloys, ceramics, and other precious metals.

SAIMENG Carbides are available in a full range of surgical, metal cutting, trimming and finishing burs. SAIMENG carbide burs promise very higher concentricity, faster and smoother cutting and improved finishing. Generally speaking, trimming and finishing carbide burs have 12 basic flutes and 30 flutes. Dentist can select the exact dental carbide burs according to their special demands.

Made of the strongest and the toughest Zirconia ceramic material, Ceramic Drill Nail bits are much more durable than carbide nail drill bits. Shank Size: 3/32" Resistant to acid, alkaline and heat, Antibacterial and no clogging.

1. good hardness and fast speed to save time

2. antibacterial and environmental

3. no clogging

4. easy to clean and disinfect

5. resistance of acid, alkali and heat

6. small size and cuspidal design

1. Intersectant stripes of the drill bits can polish and reshape your nails.

2. be used for wiping away nail gel

3. remove the dead skin for finger nails and toe nails

4. easier to remove the dead skin near your nails

5. made of ceramic and stainless steel, not easy to rust

6. storage box is provided, easier to stor