Saimeng Tungsten carbide burrs keep on excellent quality, SC type for industry use

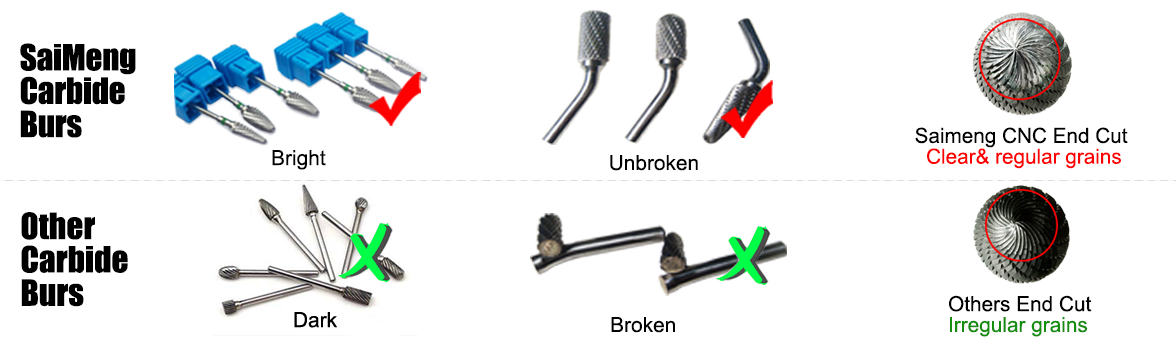

1. Saimeng Tungsten carbide burrs keep on excellent quality

2. More than 200 specifications is developed to satisfy your fully professional requirement on grinding

3. You can choose many different surface color (self-colored & not plated; Silver & nickel plated; Gold & Ti plated)

4. Keep the surface clean (Oil on surface have been got rid of by Ultrasonic)

5. Tungsten carbide burrs from Saimeng tools Beside different shapes, you can choose sizes, grain & length

Metric Size

| Tool Number | Cut Diameter | Cut Length | Shank Diameter | Overall Length |

| SC-41M | 2.5 | 11 | 3 | 38 |

| SC-42M | 3 | 14 | 3 | 38 |

| SC-42ML2 | 3 | 14 | 3 | 50 |

| SC-42ML3 | 3 | 14 | 3 | 75 |

| SC-11M | 3 | 12 | 6 | 56 |

| SC-12M | 3 | 16 | 6 | 60 |

| SC-52M | 4 | 12.7 | 3 | 38 |

| SC-13M | 4 | 16 | 6 | 50 |

| SC-53M | 5 | 12.7 | 3 | 38 |

| SC-14M | 5 | 16 | 6 | 50 |

| SC-1M | 6 | 16 | 6 | 50 |

| SC-1MNF | 6 | 19 | 6 | 50 |

| SC-1ML | 6 | 25 | 6 | 50 |

| SC-1ML6 | 6 | 12.7 | 6 | 162 |

| SC-51M | 6.3 | 12.7 | 3 | 50 |

| SC-2M | 8 | 19 | 6 | 64 |

| SC-3M | 9.5 | 19 | 6 | 64 |

| SC-3MNF | 9.5 | 19 | 6 | 64 |

| SC-3ML | 9.5 | 25 | 6 | 70 |

| SC-3ML6 | 9.5 | 19 | 6 | 169 |

| SC-3MZ | 10 | 20 | 6 | 60 |

| SC-4M | 11 | 25 | 6 | 70 |

| SC-5MZ | 12 | 25 | 6 | 65 |

| SC-5M | 12.7 | 25 | 6 | 70 |

| SC-5ML6 | 12.7 | 25 | 6 | 175 |

| SC-5MNF | 12.7 | 25 | 6 | 70 |

| SC-6M | 16 | 25 | 6 | 70 |

| SC-7M | 19 | 25 | 6 | 70 |

| SC-7MNF | 19 | 25 | 6 | 70 |

| SC-7MNF/8 | 19 | 25 | 8 | 70 |

| SC-9M | 25 | 25 | 6 | 70 |

Inch (imperial) Size

| Tool Number | Cut Diameter | Cut Length | Shank Diameter | Overall Length |

| SC-11 | 1/8 | 1/2 | 1/4 | 2 |

| SC-12 | 1/8 | 5/8 | 1/4 | 2 |

| SC-13 | 5/32 | 5/8 | 1/4 | 2 |

| SC-14 | 3/16 | 5/8 | 1/4 | 2 |

| SC-1 | 1/4 | 5/8 | 1/4 | 2 |

| SC-1L | 1/4 | 1 | 1/4 | 2 |

| SC-2 | 5/16 | 3/4 | 1/4 | 2 1/2 |

| SC-3 | 3/8 | 3/4 | 1/4 | 2 1/2 |

| SC-3L | 3/8 | 1 | 1/4 | 2 3/4 |

| SC-3X | 3/8 | 1 1/2 | 1/4 | 3 1/4 |

| SC-4 | 7/16 | 1 | 1/4 | 2 3/4 |

| SC-5 | 1/2 | 1 | 1/4 | 2 3/4 |

| SC-6 | 5/8 | 1 | 1/4 | 2 3/4 |

| SC-15 | 3/4 | 1/2 | 1/4 | 2 1/4 |

| SC-16 | 3/4 | 3/4 | 1/4 | 2 1/2 |

| SC-7 | 3/4 | 1 | 1/4 | 2 3/4 |

| SC-9 | 1 | 1 | 1/4 | 2 3/4 |

| SC-41 | 3/32 | 7/16 | 1/8 | 1 1/2 |

| SC-42 | 1/8 | 9/16 | 1/8 | 1 1/2 |

| SC-42L2 | 1/8 | 9/16 | 1/8 | 2 |

| SC-42L3 | 1/8 | 9/16 | 1/8 | 3 |

| SC-51 | 1/4 | 1/2 | 1/8 | |

| SC-52 | 5/32 | 1/2 | 1/8 | 1 1/2 |

| SC-53 | 3/16 | 1/2 | 1/8 | 1 1/2 |

| SC-61 | 3/32 | 3/8 | 1/8 | 1 1/2 |

| SC-81 | 3/16 | 5/8 | 3/16 | 2 |

1. All CNC machine lines, each customer has a special CNC database to ensure stable product quality

2. All products are tested for welding fastness

3. Technical support and email-reply will be provided within 24 hours when quality issue occurs

4. If quality issue occurs, new products will be delivered for free as compensation

5. Each product is packed in separate plastic box

6. Special tungsten carbide burrs could be customized according to the actual needs of customers

7. Laser marking is available

8. DHL ,TNT, FEDEX as long-term partners, delivered within 3-7 working day

The high-performance tungsten carbide rotary burrs provide maximum cutting edge stability with a simultaneous high tenacity of the cutting edge.

SAIMENG Tungsten Carbide Burr are ideal for shaping, smoothing and material removal. The tungsten ones are used on hardened steel, stainless steel, cast iron, nonferrous metals, fired ceramics, plastic, hard wood, especially on hard materials whose hardness can be above HRC70. To de-bur, break edges, trim, pro-cess welding seams, surface processing.

The product has long time operation life and its application range is widely, you can use different shape product according to your application. Use higher speeds for hard woods, slower speeds for metals and very slow speeds for plastics ( to avoid melting at the point of contact).

The tungsten carbide burrs are mainly driven by hand electric tools or pneumatic tools (also can be used on machine tool). The rotary speed is 8,000-30,000rpm;

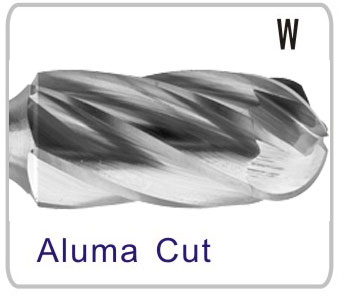

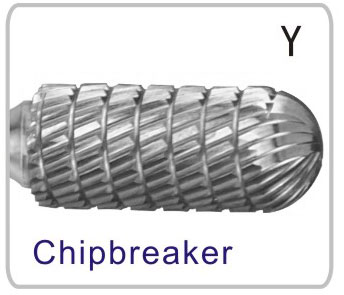

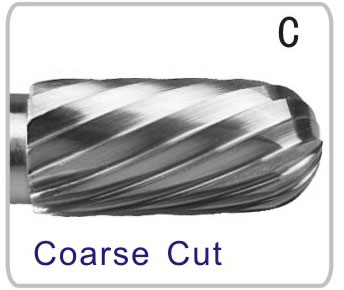

Tooth Type Choice:

Aluminum cut burrs are for use on nonferrous and nonmetallic materials. It is designed for rapid stock removal with minimum chip loading.

Chip Breaker cut burrs will reduce sliver size and improve operator control at a slightly reduced surface finish.

Coarse Cut burrs are recommended for use on soft material such as copper, brass, aluminum, plastics, and rubber, where chip loading is a problem.

Diamond Cut burrs are very effective on heat treated and tough alloy steels. They produce very small chips and good operator control.Surface finish and tool life is reduced.

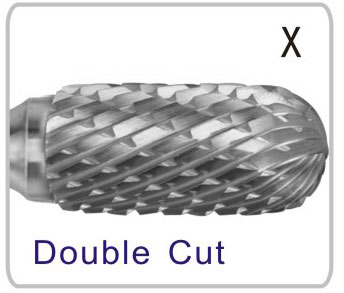

Double Cut: Chip size is reduced and tool speed can be slower than normal speeds. Allows for rapid stock removal and better operator control.

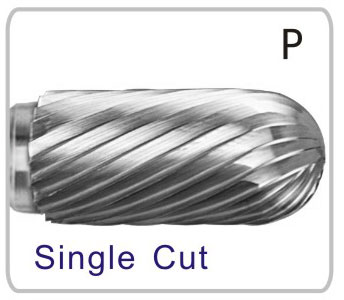

Standard Cut: A general purpose tool designed for cast iron, copper, brass and other ferrous materials. It will give good material removal and good work piece finishes.